Raised Floor History And The Convergence With Modular Construction

The right raised floor system is critical to any project application where one is needed because it allows your space to evolve with your business.

Need support for your project?

Call to speak to an advisor.

Call Now The future starts with Gridd®

At FreeAxez, helping you reach your highest levels of productivity is at the center of what we do, and has been for over 25 years.

Gridd®, the revolutionary and award-winning raised floor, enables organizations like yours to underpin your technological transformation now and into the future, by providing unified cabling solutions that dynamically respond to your workplace demands.

Businesses across a broad spectrum of industries and verticals are turning to Gridd reconfigurable, low-profile raised floors to swiftly and cost-effectively adapt to the needs of their clients and workforce while remaining cost-effective.

FreeAxez Advisors ensure you achieve your business priorities, from initial installation to client occupancy. The FreeAxez team of advisors provides ongoing support through every stage of maintaining and utilizing the Gridd system.

We see ourselves as partners in your success, and that ongoing relationship begins at your first touchpoint with FreeAxez and the Gridd Raised Floor System.

Need support for your project?

Call to speak to an advisor.

The evolution of raised floor systems

The terms “raised floor,” “access flooring,” or “raised access flooring” all refer to a construction model that elevates the building surface above the original concrete slab in server rooms. They were originally used for cooling mainframe computers and then developed to be a passage for mechanical and electrical services.

FreeAxez uses the name “raised floor” when discussing Gridd to make it easy for end users to find us. Gridd, however, is NOT a raised floor in the traditional sense. When they hear the term raised floors, most people think of post and panel construction like the floors created in the 1960s for airflow distribution to cool large mainframe computers. Today this design is usually seen in data centers where administrators manage the massive amounts of heat generated by servers.

Post and panel floors consist of a square panel on four steel posts fastened together by additional hardware and require a special large suction-cup tool to lift heavy panels. This procedure requires a qualified tradesperson and hours of labor for reconfiguration. With only one trade responsible for installing and opening and closing the post and panel system, this technology can develop substantial roadblocks when IT technology updates or office reconfigurations are required.

Post and Panel floors were originally 24-36” in height, but as computer technology advanced, the height of the floor design was lowered to 4-6”. Despite its lower height, the post and panel design remains the same.

While FreeAxez uses the term raised floor, we base the Gridd solution on an entirely different low-profile approach. Further, Gridd adapts dynamically to the needs of the space and focuses on cable distribution and management.

Pros and cons of traditional post and panel

A traditional raised floor is typically used for underfloor air distribution. It creates a sealed air space (called a plenum) between the raised access floor and the subfloor. The plenum is there to accommodate and contain underfloor air distribution (UFAD). These floors can be installed at a variety of heights, from 24 inches (610 mm) and 48 inches (1219 mm).

The height of the posts is dictated by the volume of cables and other services stored beneath the raised floor; the typical height is somewhere between 24 inches (610 mm) and 48 inches (1219 mm).

To meet commercial demands of low profile systems, traditional post and panel manufacturers have attempted to bring their raised floor heights, in some cases, down to four inches. However, at that height, post and panel flooring still doesn’t offer the usable space or flexibility that low profile systems have as a standard.

The key components of the traditional post and panel flooring system are as follows:

- Post (pedestal): This is a vertical, adjustable post that supports the floor panels mentioned above.

- The panel attaches with screws to a steel post at each corner (4 posts per panel). The posts are usually bonded to the subfloor with an epoxy resin-based adhesive and with mechanical fixings if required.

- Stringer: This is a horizontal piece of hardware that connects to the post head, adding additional lateral floor support, if needed.

- Additional structural support and lighting are often needed when a floor is raised enough for a person to crawl under.

- Added requirements may include fire suppression systems and cable tray systems.

After installation, the floor panels can be covered with a variety of flooring finishes. These include carpet tiles, vinyl files, linoleum, high-pressure laminate, rubber tiles, wood, marble, and stone and ceramic tiles.

Should repairs or changes need to be made to the services under the floor, a unique tool and a trained worker will be required. This tool (called a floor-puller, tile lifter, or suction lifter) has a curved handle atop a large suction cup.

Workers open the floor using a suction lifter, attaching to an individual tile and then lifted with brute strength. For carpet tiles, workers use a hook and loop lifter. This process took hours of labor, especially since several other factors had to be considered when using a traditional raised access flooring system, namely how to introduce cabling into the workspace.

Early designs, drawbacks and costs

FreeAxez developed the low-profile raised access floor system Gridd, because traditional raised flooring solutions were labor-intensive. Outcomes were inflexible and insufficient to address the need for long term stability, making cable management and reconfiguration—a frequent need for evolving businesses—difficult.

Following traditional raised floor methods, end users can only manage cable distribution in five ways, each involving construction crews, time and mess.

1. Running wires through walls cost businesses time and money, and the results were inflexible in terms of repurposing workspace in the future. With that, this didn’t solve the problem of getting data and power to the center of large rooms.

2. Using power poles were not aesthetically pleasing and still did not allow for flexibility should business priorities shift.

3. Using drop-ceilings, where power and data are run through the ceiling, meant installation took longer and involved going up and down ladders, making installation an incredible pain (back and neck pain that is).

4. Core drills, a technique designed to remove a cylinder of concrete in the slab, were quite costly and also inflexible and thus impractical for reconfiguring a space.

5. Trenches (a brand name) also provided built-in trenches for cables in the concrete, but these too provided a limited outcome.

Much of this approach can alter buildings in ways that may be inconvenient and permanent down the road when business priorities change. Costs rapidly increased as project managers, construction crews and delays factored in.

Traditional post and panel is rigid and heavy. Additionally, it has some costly limitations in that it can only be changed a finite amount of time before the stability of the structure begins to deteriorate.

Changes themselves can become costly in a relatively short period of time. Not only is it heavy and cumbersome to work with, but it also requires a special team and tools to work underneath it any time re-cabling or new installations occur. The post and panel approach might work in server rooms, but for flexible environments that need to adapt with the needs of people, this approach has become obsolete.

See GRIDD in action.

Low profile options and

modern workplace design

Once businesses no longer needed the high-profile version of raised flooring to manage computer equipment, designers lowered the traditional raised floor model from 24”- 36” down to 4”- 6”. However, they did so without changing from the post and panel construction model.

Though responding to the reality that business workplaces no longer needed the same under-floor cooling features of the past, developers kept things the same. This decision did nothing to improve the overall design. There are drawbacks to keeping the same construction type. For one, it can become unstable over time. Secondly, it is time-consuming to deconstruct and reconfigure, and the results are less than optimal.

Building owners and facility managers need to have the ability to adapt their space to the needs of business today and provide a way to quickly evolve with the requirements of tomorrow. When a business grows, expands, or shifts direction, raised flooring must have the capability to change with it.

With Gridd, there is no deterioration of the system when it is opened and closed, and can be changed an infinite amount of times

For a post and panel system, changes and drawings have to be provided by and certified by an engineer; while with Gridd you just install the system and go, and the steel construction and rock-solid component technology means the system stays strong. In fact, Gridd lasts for the life cycle of the building

Intersection with modular construction

Organizations can replace traditional construction methods, both cost-effectively and efficiently, using modern manufacturing techniques of combining built and modular elements.

Manufacturing for construction can bring cost down and realize quality transformations. Planning for future reuse will facilitate easy dismantling and repurposing off-site manufactured buildings or portions of buildings.

The research team at Gensler Research Institute, in a study on the trend toward modular construction, published a study entitled The Prefab City. They found mounting evidence of this trend toward reconfigurable construction:

“We stand at the brink of a potential new era of construction manufacturing. We will continue to explore multiple construction disciplines, product manufacturers, and governmental agencies to define the future of prefab construction further. Additional efforts will develop practical guidelines that will assist architects, consulting partners, and clients to transform the future of construction to be more efficient, cost-effective, and resilient.”

Resilience and adaptability are essential qualities in a construction environment where ensuring longevity of a financial investment makes you more competitive, even if that’s not your primary industry.

Gridd raised floor systems

are modular in design

The modular design of Gridd raised floor technology allows building owners and facility managers the ability to adapt their space to their needs today and tomorrow. When a business grows, expands, or shifts direction, Gridd flooring can change with it. Unlike other fixed flooring options, you can literally pick up the Gridd system and take it with you.

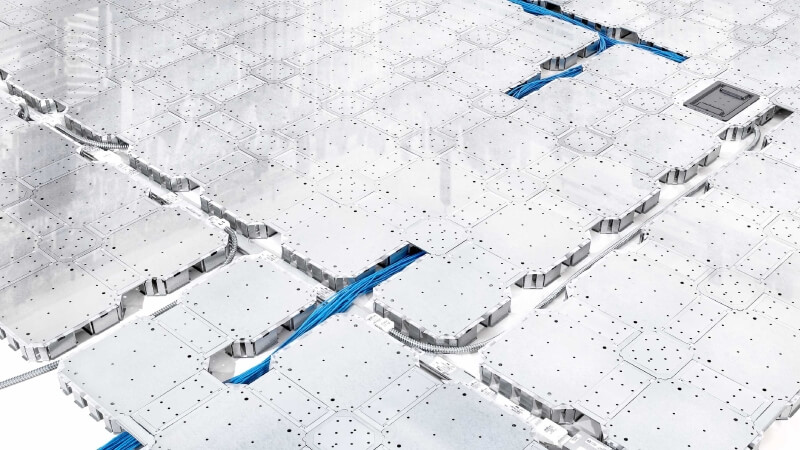

Gridd can be installed without tools or fasteners. One installer can install thousands of square feet per day. No tools mean faster installation and lower installation costs. Gridd goes together like Legos, but is made of 100% steel, making it environmentally friendly, superior to molded plastic flooring, and made to last a lifetime.

Technology and cable management for buildings

Gridd, the patented flagship product by FreeAxez, provides buildings the ability to route and hide all information cables in an accessible and adaptable, low-profile, all-steel structure right under their feet.

The Gridd system is a Whole Building Design approach that integrates cable distribution technology throughout the entire building infrastructure. It enables a building to adapt to inevitable technology changes, remain highly functional and operational, and saves money at every stage of its life cycle. Gridd offers seamless cable integration to support your power and cable infrastructure with accessories that adapt to fast-changing technology.

Gridd 40 – Gridd 40 at only 1.6” (40 mm) is the lowest height option of the Gridd system. The Gridd 40 system has a load capacity of 2,000lbs – 100 PSF. Ceiling height or transition limitations are best accommodated with Gridd 40. ADA compliant ramp at 1:12 only 19” long. 1:20 slope is 33”.

Gridd 40 Reinforced System – The Gridd 40 Reinforced system offers the same benefits of the standard Gridd 40 system but is reinforced to accommodate “heavy” floor load conditions as by the International Building Code (IBC). The reinforced system is often used in high traffic areas such as museums, airports, and other public spaces. The Gridd 40 Reinforced system has an increased load capacity from the standard Gridd40 system (3,000lbs – 250PSF).

Gridd 70 System – Gridd 70 at 2.75” (70mm) is the highest height option of the Gridd system. The Gridd 70 system has a load capacity of 2,000lbs – 100 PSF. Intense cable distribution requirements may best be served with Gridd 70. Gridd 70 has longer ramps (1:12 slope is 33″, 1:20 is 55″). Gridd Power is compatible with Gridd 70.

Gridd 70 Reinforced System – The Gridd 70 Reinforced system offers the same benefits of the standard Gridd 70 system but is reinforced to accommodate “heavy” floor load conditions as by the International Building Code (IBC). The reinforced system is often used in high traffic areas such as museums, airports, and other public spaces. The Gridd70 Reinforced system has an increased load capacity from the standard Gridd70 system (3,000lbs – 250PSF).

The Gridd System is designed for efficient cable management and distribution. Anywhere cable management is needed, Gridd optimizes your flexible workspace for every application listed on the FreeAxez website as well as offices, laboratories, broadcast studios, airports, control rooms, government and more.

A cabling distribution system for cable and power management

Gridd revolutionized the approach to underfloor cabling distribution. It is based on an entirely different technology that is built to last for the life cycle of your building. To see the difference you only need to see it in a side-by-side comparison with post and panel technology floors.

It is so unique that in 2009, the CSO and CSA designated the following MasterFormat number and title for this newer generation of raised flooring systems:

09 69 33 – Low Profile Fixed Height Access Flooring

For over 50 years, the post and panel raised floor has been seen as a raised floor, and it still serves the same purpose today: air distribution.

However, with the explosion of information technology and audio-visual innovation of the early 21st century, modern building requirements changed rapidly and dramatically. There was a need for an alternative approach to raised flooring systems.

What evolved was a raised floor solution for underfloor cable management, power distribution, and connectivity for the now-wider range of applications where air distribution was not needed.

Low profile flooring is not a replacement for traditional post and panel if the purpose is for underfloor air distribution. Low profile flooring is a flexible and adaptive solution for cable management in applications where air distribution is not a concern.

The key components of a low profile raised access flooring system are as follows:

- Floor Panel: This is the horizontal load-bearing component of the floor. Each panel is a square tile, usually the standard size of 2 by 2-feet. The panels come in a variety of materials, such as concrete with steel core, hollow steel, bare concrete, and wood; there is one product that is all steel. Each panel is lightweight.

- Post (pedestal): This is a vertical, adjustable post that supports the floor panels mentioned above. The panel attaches with screws to a steel post at each corner (4 posts per panel). The height of a low profile floor is between 1.5 inches (38 mm) and 6 inches (152 mm).

- There is one product that is manufactured with integral support, meaning that there are no posts. It is a gravity-held system that is not secured to the concrete.

After installation, the floor panels can be covered with a variety of flooring finishes, such as carpet tiles, vinyl tiles, linoleum, high-pressure laminate, rubber tiles, wood, marble, and stone and ceramic tiles.

Adaptive building tech

made for flexibility

Now more than ever, the need for adaptive workspace technologies is clear. Those operations that have embraced this approach and invested in flexible infrastructure components, including raised floor systems, are leveraging this advantage to provide highly-responsive environments.

For more than 25 years, FreeAxez has led the industry in developing new low profile access floor systems that accommodate changing technology and adapt to future changes quickly.

FreeAxez is widely accepted as the premium developer, innovator and manufacturer of adaptive cabling distribution systems. We have a proven system of products and are continuously expanding and refining

FreeAxez’s range to meet today’s and tomorrow’s integrated high-performance buildings. Unlike other fixed flooring options, you can pick up the Gridd system and take it with you. This ‘can do’ approach to demanding projects and commitment to stay ahead of the industry’s evolving needs is what FreeAxez’s clients depend on.

The FreeAxez Commitment

FreeAxez has an allegiance to innovation and creativity, and is positioned to respond to the rapid changes in the industry. It is a pleasure to take on the toughest problems for customers both now and in the future. Gridd is an evergreen solution, and is backed by the 25-year promise that Gridd products will continue to interconnect with the newest components. All newly developed products can continue to be incorporated into systems installed 25 years ago.

The world is changing:

- Economic volatility is perhaps the foremost challenge on everyone’s mind.

- Climate control is equally important.

- New technologies continuously disrupt every industry in the world.

- The future is uncertain.

FreeAxez is committed to helping clients take on the ever-changing challenges of the modern world. As it has done for over 25 years, FreeAxez will continue to develop products that meet the needs of facility managers, architects and end users.