Need support for your project?

Call to speak to an advisor.

Call Now A Raised Floor That Moves and Evolves with Your Workplace

When people hear the term “raised flooring system with power,” they often envision the old-fashioned computer flooring systems that debuted in the 1960s. The primary goal of these was to create a plenum for cooled air while hiding the miles of cable required for power and data.

Unfortunately, these raised flooring systems were not very installer or user-friendly. Installers must work on their hands and knees while installing the pedestals, stringer supports, and the power and data runs. Floor panels (typically steel or concrete) are heavy and cumbersome to handle and cut during the original construction process and for tenant upgrades or changes.

Today’s Raised Flooring Systems

Without the need to provide cooled air, low-profile raised flooring systems quickly replaced those expensive and outdated computer flooring systems. In fact, the Construction Specifications Institute (CSI) and the Construction Specifications Canada (CSC) designated new Master Format numbers and titles for standardized raised flooring systems:

- 09 69 00 – Raised Access Flooring

- 09 69 13 – Rigid Grid Access Flooring

- 09 69 33 – Low Profile Fixed Height Access Flooring

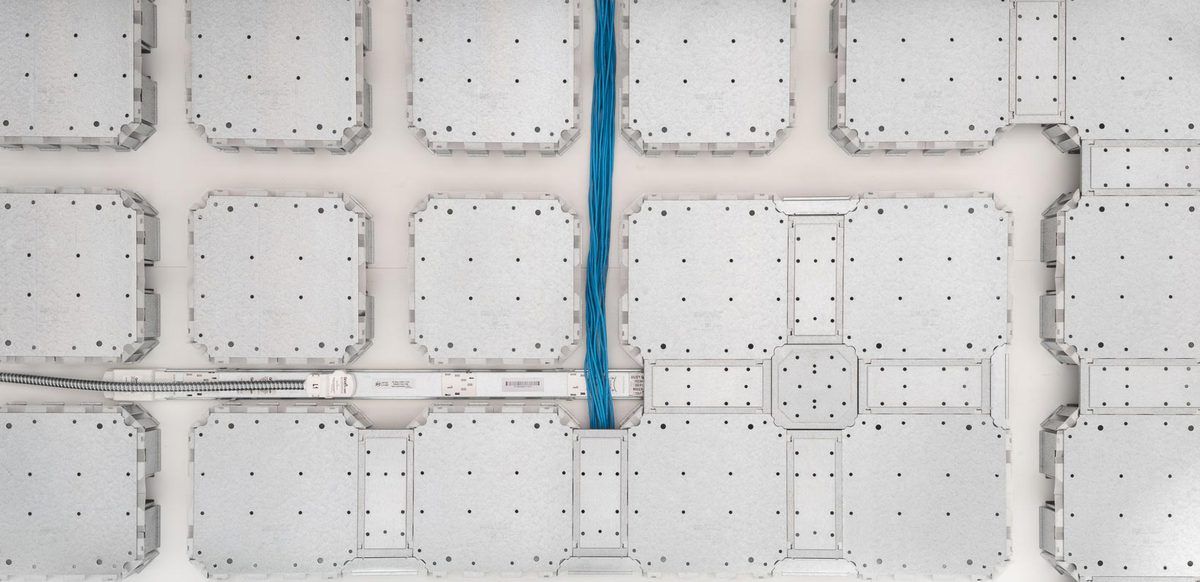

Most raised flooring systems, such as the Gridd® Adaptive Cabling Distribution® System, create a small air gap of 3” or less for all the needed data cabling runs. But unlike other options, the Gridd system features all-steel components for increased strength and durability. We’ve also eliminated the myriad of special fasteners and tools required and purposely limited the number of different components needed for a Gridd installation.

Gridd Field Units

Base unit (1.6” or 2.75” FFH)

Corner plate

Channel plate

Optional components for higher weight capacity demands:

Reinforced channel plate

Reinforced corner plate

You can see a complete component list here.

As tenants’ needs change, their installers can simply remove the needed floor panels and perform the work without having to open walls and ceilings to add new workstations or repurpose existing areas.

But why stop with the data cabling?

Level up your ROI with Gridd® Power. With the electrical power distribution system underfoot and the data cabling, you can reduce future electrical upgrade costs as well.

How Does Gridd Power Work?

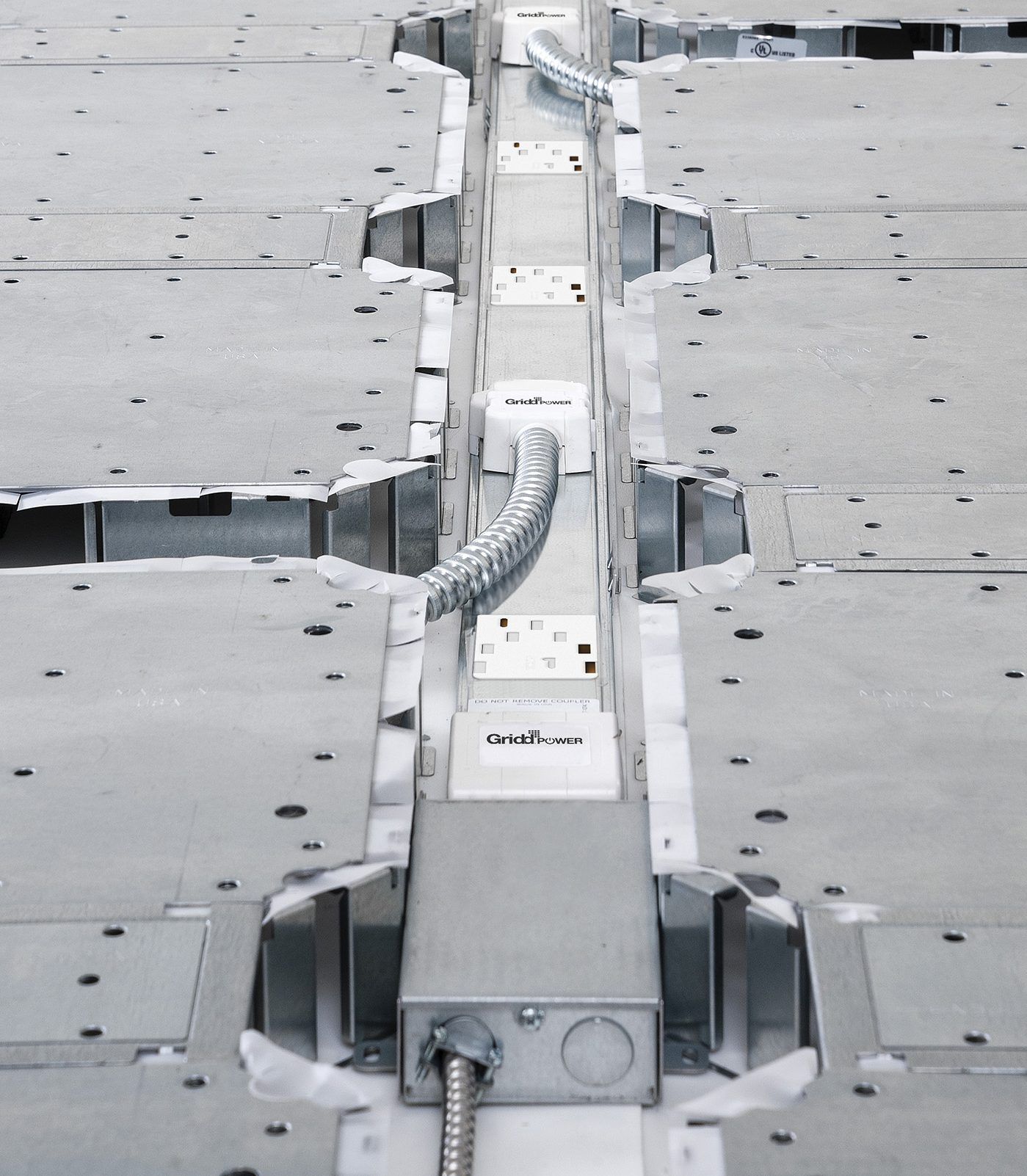

Gridd Power is a power distribution solution installed within the cable management flooring system. There are two distribution systems available: track distribution and field wired.

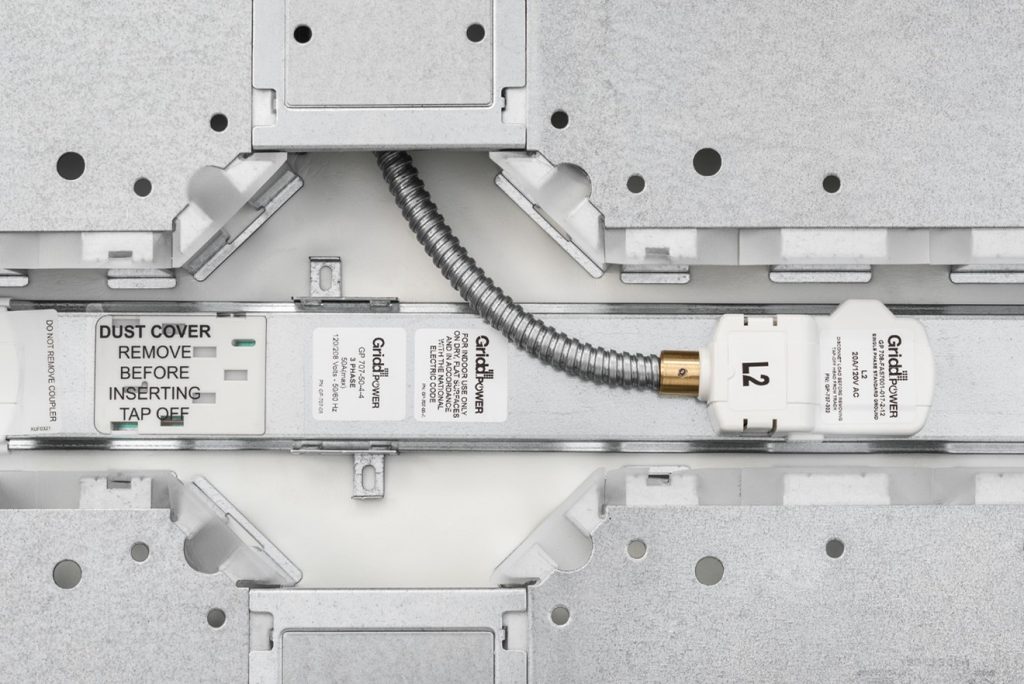

- The track distribution system provides the equivalent of a 50A three phase subpanel in the floor. All electrical components connect with a tap-off whip.

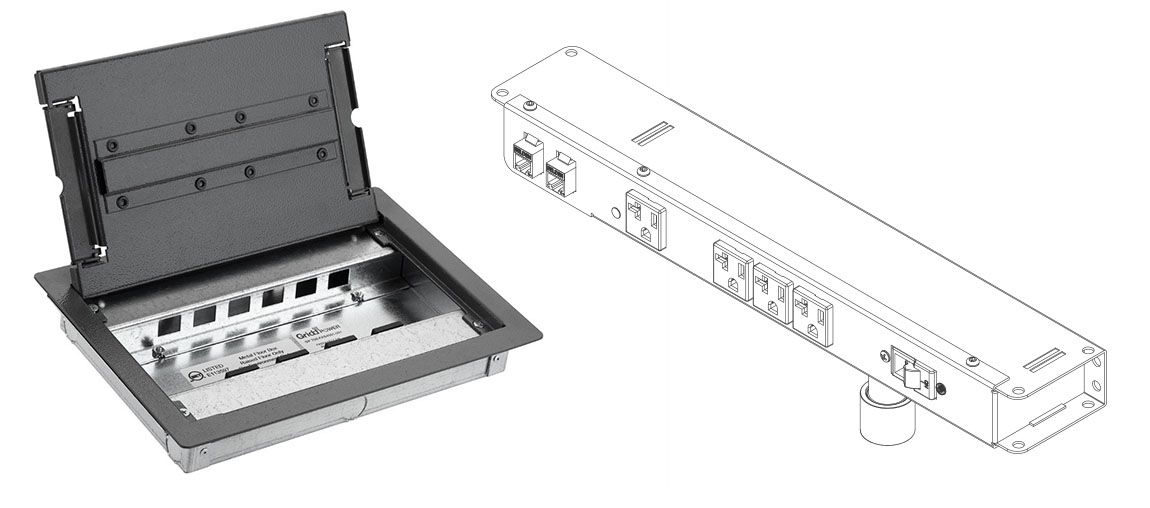

- The field-wired components provide a traditional branch circuit supply with floor boxes or furniture mounted receptacle and data modules.

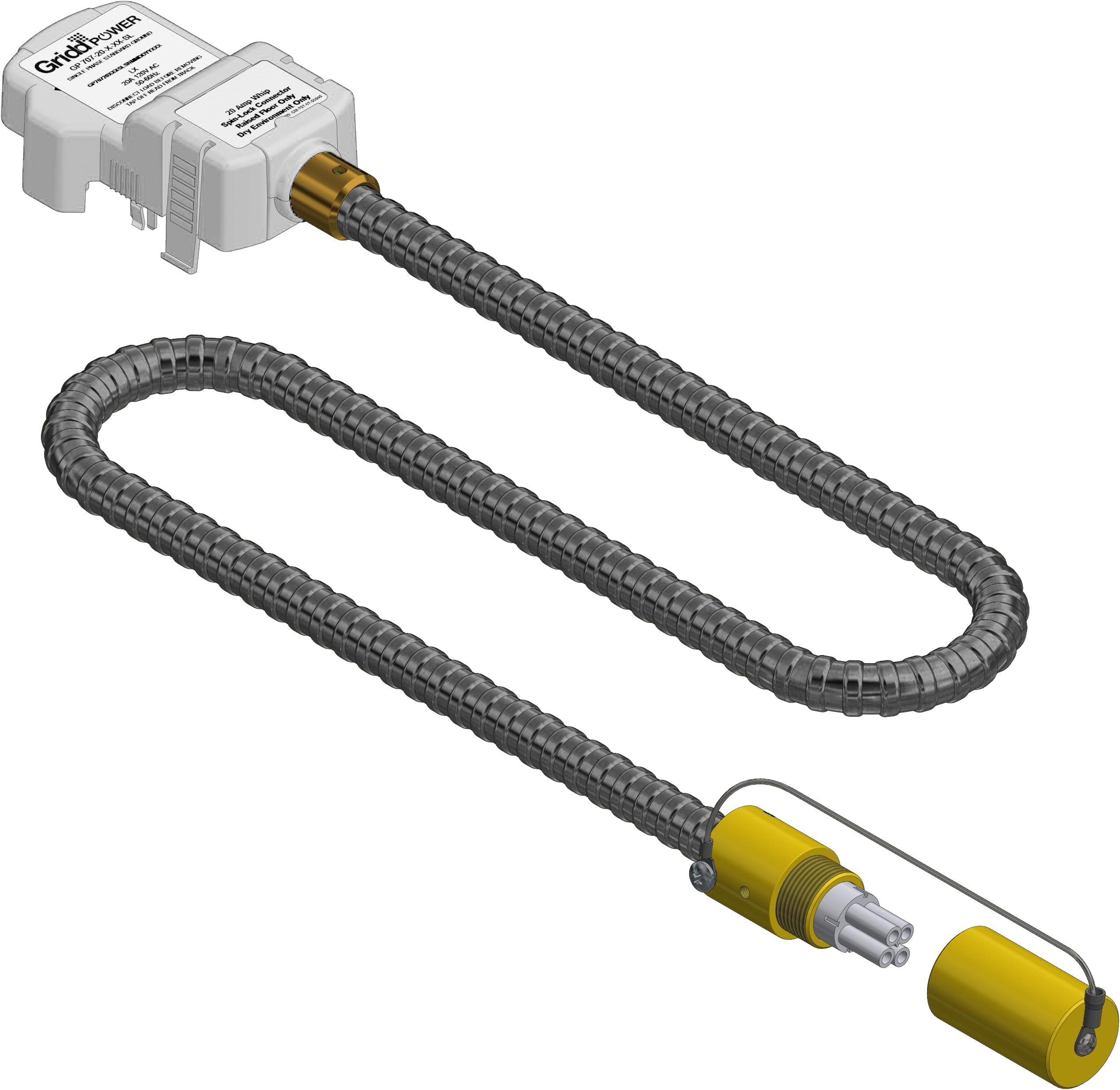

- Both the track and field-wired systems can be equipped with the added flexibility of spin lock connectors.

Track Distribution System: The heart of the track distribution system is a 50A feed module wired from the electrical panel to the power track. The track is located in the floor available to provide power to wall receptacles, wired furniture, and equipment such as floor boxes, printers, copiers, tech panels, etc. The number of 50A tracks is determined by the power requirements of the area served. The spacing of the tracks is designed to provide accessibility anywhere in the area so it will meet the initial floor plan design as well as accommodate any future changes and space reallocation without the need to run wiring back to the electrical panel.

Track is also available as a 20A branch circuit system.

Components of the Track Distribution system:

Feed Modules provide the source of power. 50A three phase or 50A dual circuit connections preassembled with MC cable whips. The cable whips are assembled in lengths required to reach the panel. Isolated Ground and Energy Control circuits can be accommodated.

Tracks are bus bar assemblies in 4’ and 8’ lengths with receptacle taps every 12 inches. Tracks are coupled together in the lengths needed to serve the area. Both the length and spacing of the track assemblies are designed to provide full access to power anywhere in the floor plan.

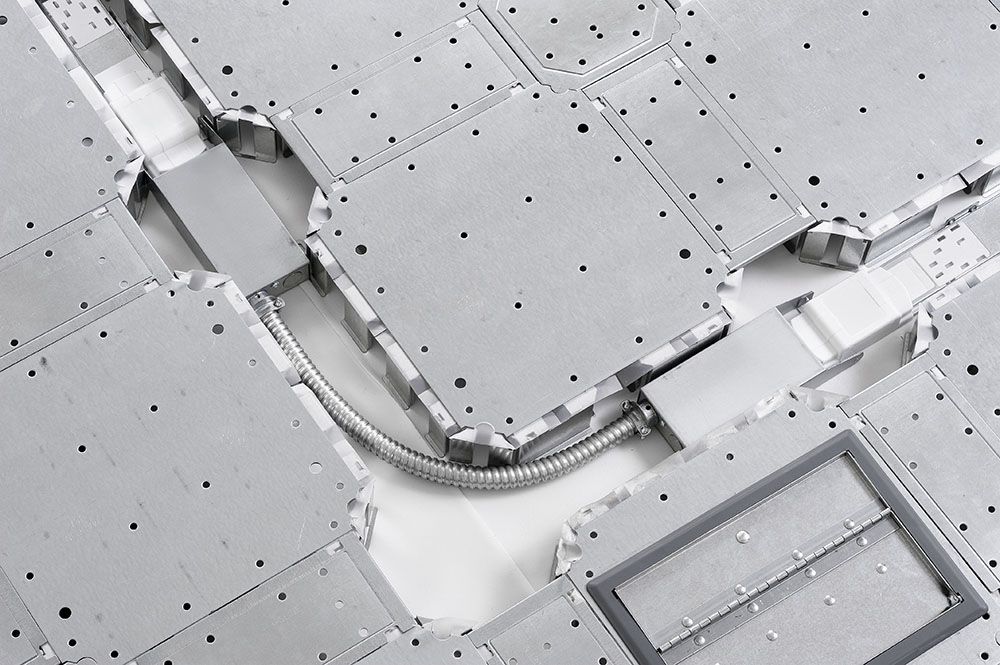

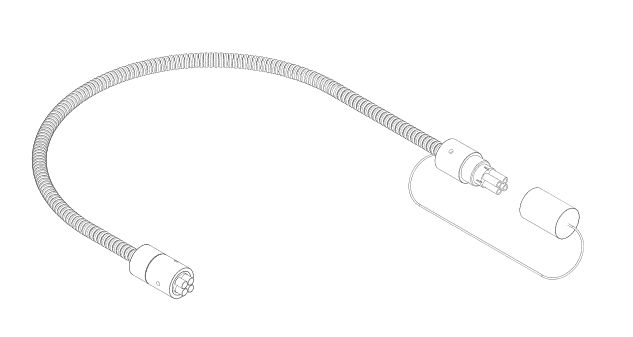

Interlink is a flexible coupling that extends the track assembly, permits it to pass through walls or turn within the floor system to reach different areas. Length is determined by the installation parameters.

Electrical Components connect to the track through a receptacle and plug connection. The components incorporate circuit breakers to provide branch circuit overcurrent protection.

All components of the system are available with optional spin lock connectors.

Branch Circuit Field Wired components:

All components available in 2 options.

Option 1: Field wired where the electrician provides the wiring method and all connections are completed in the field.

Option 2: Factory supplied MC cable in pre-determined lengths with spin lock connectors that can carry 1 or 2 circuits. Floor boxes and furniture mounted receptacle and data modules are connected with spin lock fittings.

Also available is a branch extension to daisy chain components together.

Power and Cable Distribution Strategies

In today’s tech driven economy, building owners cannot reasonably expect tenants to provide the data and cabling needed for upgrades, increased capacity, or IoT connectivity.

Part of the design stage involves fully minimizing future outages and disruptions for both vertical cabling infrastructure across each floor and the horizontal cabling contained within the raised flooring system.

As a result, architects, designers, and engineers must consider the following four variables for each new project or remodel.

Power – Streamlining the power delivery system can be a daunting task. However, the bus bars utilized in the Gridd Power system are specifically designed to distribute power effectively throughout a suite. Tools, devices, and electronics work better without the problematic voltage drops seen in other systems.

Security – As the IoT and smart cities continue to evolve and grow, so will security concerns. Most data security involves software and firewalls, but data and power cables located within the raised flooring system are much less susceptible to damage and unauthorized access.

Cabling Access – With the cable management system underfoot, changes and upgrades are quick, easy, and require minimal disruption to tenants and workers.

Planning – Companies should keep pace with new and expanding technologies to avoid future disruptions and setbacks. The plug and play design of Gridd Power allows companies to design with the future in mind to decrease future construction and maintenance time and costs.

With a global Compound Annual Growth Rate (CAGR) of 9.2% through 20281, the cabling market will continue to grow to meet the rising demand created by wireless usage, data transfers, remote education and medical services, the continued growth of the IoT (Internet of Things) and smart city deployments.

Green Building Benefits

Green building reduces construction waste by promoting efficiency throughout every phase of a construction project. Green buildings typically promote resilient designs, materials, and construction methods to reduce waste and water energy usage, in turn reducing carbon emissions in the process.

Globally, sustainable buildings provided $7.5 billion in water and energy savings to property owners and another $5.8 billion in disposal and environmental cleanup costs2.

In addition to saving money, tenants and employees have reported the societal benefits of green buildings, which include3.

- Reduced stress levels

- Improved emotional functioning

- Increased communication

- Stronger community identity

However, these social benefits are clearly visible when comparing annual public health costs. A 20182 study by the National Center for Biotechnology Information determined that green buildings saved the US health system $5.4 billion by preventing.

- 172-405 premature deaths

- 171 hospital admissions

- 11,000 asthma exacerbations

- 54,000 respiratory symptoms

- 16,000 lost days of school

- 21,000 lost days of work

As we can see, the benefits of flexible and adaptable building design extend far beyond the property to positively impact the well-being of the entire local community.

Raised Flooring Installation Process

Raised Flooring Installation FAQs

Q: How long does the raised flooring installation require?

A: Since Gridd installs without any special adhesives, fasteners, or tools, installers can assemble approximately 1,000 square feet of base units per day.

Q: Does a raised flooring system need to be grounded?

A: No. Much like steel stud framing systems that contain data and power cables, there is no requirement to ground the Gridd raised flooring system.

Grounding of the Gridd System is not a requirement by any electrical code. An underlayment separates the steel components from the existing slab, eliminating the need for a grounding connection.

Q: What are my finish flooring options?

A: Any flooring material that can be installed over a standard slab is acceptable. Common finishes include carpeting, LVT (Luxury Vinyl Tile), laminate flooring, VCT (Vinyl Composition Tile) and linoleum. Modular floor covering is recommended to maintain accessibility and flexibility.

Q: How do I access the cabling for changes or upgrades?

A: Remove the finish flooring in the desired area and remove the channel or corner plates to access the affected cables. When finished, reinstall the plates and floor finish.

Gridd: The Leader in Raised Flooring Systems

For over 20 years, FreeAxez has continually refined the Gridd raised flooring system around four key design elements.

Flexibility

Construction projects, upgrades, and remodels come in all shapes and sizes. As a result, architects and designers need a singular raised flooring system that works just as well in a small tenant improvement project of 15,000 square feet, as it does for a 100,000 square foot office building.

Adaptability

Compared to traditional construction methods, Gridd can easily handle cabling needs today and 20 years from now. No matter what new must-have technology becomes available, Gridd can adapt to changing data and power cable needs.

Recyclable

Constructed from mild steel, the entire system can be easily recycled without having to sort out any metals or plastic components. More than 80 million tons of steel get recycled annually in North America. For every ton of recycled steel, 2,500 pounds of iron ore, 1,400 pounds of coal, and 120 pounds of limestone are saved.

Reusability

After removing the finish flooring, the entire Gridd system can be carefully reinstalled at your new location without any adhesives, fasteners, or special tools required.

As you can see, the future is here today!

The Gridd Raised Flooring System can be customized to meet the complex business needs today, while planning for future growth. As upgrades or renovations become necessary, the required work will cost less, and have a shorter project timeline, compared to traditional processes.

To learn more about how a raised flooring system can reduce future construction costs while improving flexibility and adaptability concerns, connect with one of our project advisors.