What is a raised floor?

Also called raised flooring, access flooring, or low profile flooring, a raised floor is a construction model in which an elevated floor is built above a building’s original concrete slab surface, thereby creating a hidden void between the two floors that is used for the passage of mechanical and electrical services.

Need support for your project?

Call to speak to an advisor.

Call Now What is a raised floor?

Also called raised flooring, access flooring, or raised access computer flooring, a raised floor is a construction model in which an elevated floor is built above a building’s original concrete slab surface, thereby creating a hidden void between the two floors that is used for the passage of mechanical and electrical services.

There are two general types of raised floors:

- Traditional/Standard Access Floor (Post and Panel Raised Floor)

- Low Profile Access Floor (Cable Management Floor)

The type of raised floor needed depends upon several considerations:

- Application type (data center, office, medical facility, industrial site, etc.)

- Cooling system/air distribution setup

- Cabling/Wiring needs (flexibility, routing, distribution and delivery)

Let’s take a look at each of these raised floor types and what they are designed for.

Traditional Post and Panel Raised Floor

A traditional raised floor used for underfloor air distribution

The Construction Specifications Institute (CSI) and Construction Specifications Canada (CSC) have designated the following Masterformat numbers and titles for this standard type of raised flooring:

09 69 00 – Raised Access Flooring 09 69 13 – Rigid Grid Access Flooring

The traditional post and panel raised access flooring system was introduced in the 1960s with the primary purpose of providing cooling and air flow to the large computer mainframes of that era, as they ran exceptionally hot.

A traditional access floor creates a sealed air space (called a plenum) between the raised access floor and the subfloor. The plenum is there to accommodate and contain underfloor air distribution (UFAD). These floors can be installed at a variety of heights, from 6 inches (152 mm) to 4 feet (1.3 m), or higher.

The height of the posts is dictated by the volume of cables and other services to be stored beneath the raised floor; the typical height is somewhere between 24 inches (610 mm) and 48 inches (1219 mm).

To meet industrial demands of low profile systems, traditional post and panel manufacturers have attempted to bring their raised floor heights, in some cases, down to four inches. However, at that height, post and panel flooring still doesn’t offer the usable space or flexibility that low profile systems have as a standard.

The key components of the traditional post and panel flooring system are as follows:

- Post (pedestal): This is a vertical, adjustable post that supports the floor panels mentioned above. The panel is attached with screws to a steel post at each corner (4 posts per panel). The posts are usually bonded to the subfloor with an epoxy resin-based adhesive and with mechanical fixings, if required.

- Stringer: This is a horizontal piece of hardware that connects to the post head, adding additional lateral floor support, if needed.

- Additional structural support and lighting are often needed when a floor is raised enough for a person to crawl or even walk through.

- Added requirements may include fire suppression systems and cable tray systems.

After installation, the floor panels can be covered with a variety of flooring finishes, such as carpet tiles, vinyl files, linoleum, high pressure laminate, rubber tiles, wood, marble, and stone and ceramic tiles.

Should repairs or changes need to be made to the services under the floor, a special tool and a trained worker will be required. This tool (called a floor-puller, tile lifter, or suction lifter) has a curved handle atop a large suction cup. To open the floor, the suction lifter is attached to an individual tile and then lifted with brute strength. For carpet tiles, a hook and loop lifter is usually used.

There are several things to consider when using a traditional raised access flooring system.

Need support for your project?

Call to speak to an advisor.

Hazards and Challenges Beneath a Raised Floor

Structural problems, such as rocking panels or gaps between the panels, can cause significant damage to equipment—or even lead to the injury of personnel. It is vital to look out for problems like these by conducting regular inspections to check out the structural integrity of the flooring system. This practice will help identify and mitigate any problems before damage is done or people are hurt.

These types of problems can be mitigated if the installation process is done correctly in the first place. During installation, special attention must be paid to the condition of the subfloor. The subfloor should be clean of all debris and be as level as possible. And the walls surrounding the raised floor need to be as square as possible. This will minimize the need for cutting the panels, which, in turn, will minimize panel rocking and gaps.

Another thing to avoid is flooring that does not meet the load demands of the work space. Load ratings range from 1,000 to 25,000 pounds. The panels can be mixed by using lower-weight panels in the lighter load areas of the building, while using higher-weight panels in heavy load areas of the room.

In summary, traditional post and panel raised access flooring systems are a good solution when heavy duty systems like air distribution are required. Outside contractors or highly-trained inside personnel will be necessary to service these floors.

This flooring system does not provide easy access to the wires, cables, and pipes under the floor. The individual panels are heavy and require the use of a special tool to access the plenum. Also, it is not advisable to pull too many floor panels at once, as the entire floor can lose stability; this can be a major problem if you are several feet off the ground.

There are several other types of raised flooring systems available that are a little different from the traditional post and panel model. These primarily have a telecommunications/data center application.

Current applications of the raised access floor

In today’s world, raised access flooring is primarily used in IT data centers and computer rooms where there is a requirement for UFAD. All cabling and wiring are routed under the floor as well.

A telecommunications facility is usually made up of continuous lineups of equipment cabinets. These data centers often have the most populated installation configuration in terms of square foot area, and, therefore, the heaviest floor load anticipated for a raised floor system.

Moreover, data centers are often located in remote locations and are subject to physical and electrical stresses from sources such as fires and electrical faults.

In data centers, isolated air-conditioning zones are often associated with raised floors. Perforated floor tiles are placed beneath computer systems to channel cool air directly into them. In turn, the computing equipment is designed to draw conditioned air from below into the room. Then an air conditioning unit draws the air from the room, cools it, and forces it back beneath the perforated tiles of the raised floor, thus completing the cycle.

Traditional post and panel raised floors are not used in a telecommunications/data center environment. Several different types of raised flooring systems can be employed instead and are bullet pointed below.

- Stringerless raised floors: With this system an array of pedestals (posts) provide the necessary height for routing cables and also support each corner of the floor panels. No horizontal stringers are required.

- Stringered raised floors: This system is composed of an array of steel pedestal assemblies (that consist of a steel base plate, a tubular upright, and a head) that are uniformly spaced on 2-foot centers and mechanically fastened to the concrete floor.

- Structural platforms: The components of this system are constructed of steel angles or channels that are welded or bolted together to form an integrated platform used to support equipment.

- Truss assemblies: This system utilizes attachment points to the subfloor to support a truss framework on which the floor panels rest. The truss has high lateral strength and transfers lateral loads to the subfloor with less strain than a vertical pedestal assembly does.

Now, let’s move on to the second type of raised floor system.

Low Profile Raised Floor (also called Cable Management Floor)

A cabling distribution system for cable and power management

In 2009, the CSI and CSA designated the following Masterformat number and title for this newer generation of raised flooring systems:

09 69 33 – Low Profile Fixed Height Access Flooring

For over 50 years, the post and panel raised floor has been seen as a raised floor and it still serves the same purpose today: air distribution.

However, with the explosion of information technology and audio-visual innovation of the early 21st century, modern building requirements changed rapidly and dramatically. There was a need for an alternative approach to raised flooring systems.

What evolved was a raised floor solution for underfloor cable management, power distribution and connectivity for the now-wider range of applications where air distribution was not needed.

Low profile flooring is not a replacement for traditional post and panel if the purpose is for underfloor air distribution. Low profile flooring is a flexible and adaptive solution for cable management in applications where air distribution is not a concern.

The key components of a low profile raised access flooring system are as follows:

- Floor Panel: This is the horizontal load-bearing component of the floor. Each panel is a square tile, usually the standard size of 2 foot by 2 foot. The panels come in a variety of materials, such as concrete with steel core, hollow steel, bare concrete, and wood; there is one product that is all steel. Each panel is lightweight.

- Post (pedestal): This is a vertical, adjustable post that supports the floor panels mentioned above. The panel is attached with screws to a steel post at each corner (4 posts per panel). The height of a low profile floor is between 1.5 inches (38 mm) and 6 inches (152 mm).

- There is one product that is manufactured with integral support, meaning that there are no posts at all. It is a gravity-held system that is not secured to the concrete. This product will be discussed later.

After installation, the floor panels can be covered with a variety of flooring finishes, such as carpet tiles, vinyl tiles, linoleum, high pressure laminate, rubber tiles, wood, marble, and stone and ceramic tiles.

Beneficial Characteristics of Low Profile Flooring Systems

These days facilities have an overriding need to quickly and easily make changes to their technology and floor plan configurations. Low profile raised floor systems have the following beneficial characteristics that help to solve modern office challenges:

- Movable and customizable. Since raised access flooring comes in lightweight, modular components, flooring can be added to or moved according to the needs of the office. As new technologies crop up, these floors can be added to the existing system, as at some time, every business enterprise will need more networking cables. The floor can be quickly opened up to run new cables. Expansion and updating an operation can be done quickly without paying for expensive renovation.

Open-floor spaces are currently a trend used by many Fortune 500 companies. A low profile raised flooring system will help facilitate the reconfiguration of chairs and desks. These changes require less time and are made with greater ease.

- Improves office safety and cleanliness: Safety is always a priority. Low profile raised access flooring conceals troublesome cables under the floor and puts them out of sight, eliminating tripping hazards as well as the need to work on ladders to access wiring in the ceiling.

Low profile raised access flooring tucks cables safely under the floor and promotes a clean, professional environment. Cables running along the floor, up posts or hanging from the ceiling are an eyesore that are completely removed by a low profile cable management system.

- Is cost effective: Some low profile raised floor systems are NOT attached to the building itself. Anything attached to the building stays with the building. With an unattached flooring system, should a tenant move to another building, the floor can be taken to the new space along with the office furniture. Non-attached flooring is considered to be office equipment and as such can be depreciated on tax returns.

In addition, since the underfloor cabling is not a plenum, the expense of plenum-rated cable is not required.

- Maximizes vertical space: In the past, many architects, property managers and business owners have been reluctant to utilize raised floors in workplace environments. The most common reason for this is when professionals think of raised floors, they think of the traditional post and panel floor that is often several feet high. While this type of flooring system is practical in industrial applications, most commercial buildings just cannot afford to lose several feet of floor-to-ceiling height.

With the advent of low profile raised access flooring, which is primarily used for cable management, nearly any type of company can benefit from its use.

What industries benefit from low profile raised access flooring systems?

Applications For Low Profile Raised Access Flooring

This type of cable management system works best for the following enterprises:

- Offices

- Call Centers

- Command Centers

- 911 Call Centers

- Libraries

- Classrooms

But not all low profile cable management systems are the same.

What Is Gridd Raised Flooring?

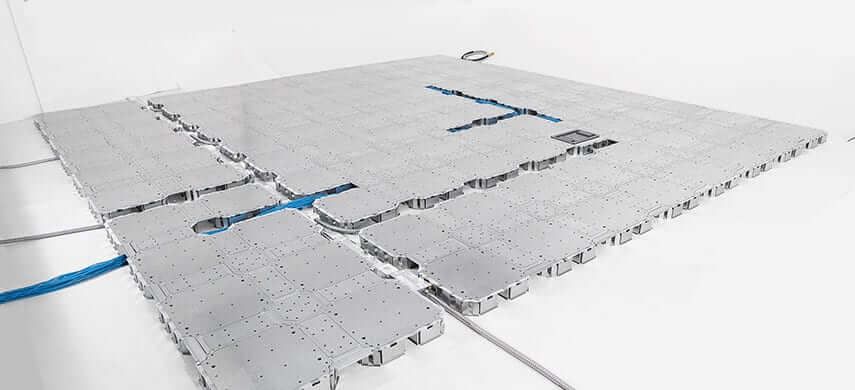

An Adaptive cabling distribution system for cable and power management

The Background

With the advent of the Gridd Raised Access Floor Cable Management System, a new raised floor concept was introduced. This innovative, new engineering design of adaptive cable management literally changed the access floor industry.

Gridd was developed 21 years ago by FreeAxez to meet the needs of flexible design, cable management, technology and smart buildings. FreeAxez leads the industry in developing new, low profile systems, and is widely accepted as the premium developer, innovator, and manufacturer of adaptive cabling distribution systems.

So, why is adaptability so important?

The Problem

Today’s modern workplace environments require an abundance of power, voice, and data equipment—and that means lots of wires, cables, and connection points.

Likewise, offices have changed vastly over the past 10 years. New technology and new workplace philosophies demand more flexibility and adaptability from all stakeholders of a commercial organization. In addition, corporate facilities must retain the power to change in the face of constantly-evolving environmental and structural codes in building architecture, design and office fit out. In order to accommodate the trend toward open office and movable furniture, there must be an equally adaptive cable management system.

Now, let’s talk about Gridd.

The Products

Gridd flooring comes in two sizes:

- Gridd40 at a height of 1.6 inches (40 mm)

- Gridd70 at a height of 2.75 inches (70 mm)

Both Gridd systems have the following components (all made from 16 gauge zinc galvanized steel):

- Base unit: 14.6” x 14.6” (370 mm x 370 mm)—weight is 1.5 pounds

- Corner Plate (for Gridd40)—Reinforced Corner Plate (for Gridd70)

- Channel Plale (for Gridd40)—Reinforced Channel Plate (for Gridd70)

- Under Sheet

- Border Components: Half Unit, Quarter Unit, Half Channel Plate, L Type Border, End Cover, Reinforcing Band, Trapezoid Plate, L Type Trapezoid Plate

Further specifications::

- Gridd40 can accommodate 50 CAT 5 cables every 15 inches @ 40% capacity—more than sufficient for any office.

- Gridd flooring, although very lightweight, is 3 times as strong as any building codes require.

- Each Gridd base unit has 34 legs stamped out of it which gives the flooring integral support and stability.

- And Gridd is 100% recyclable as it is made entirely of steel and has no plastic components whatsoever.

- Gridd both forces and provides organization of cable wiring–unlike traditional post and panel–within the floor, improving efficiencies in power and data delivery. It also provides a natural separation of both secured and unsecured cabling (NIPR/SIPR).

Now, let’s discuss just how all these components are put together:

How Is a Gridd Access Raised Floor Constructed?

The installation of a Gridd Raised Access Floor Adaptive Cabling Distribution System is the easiest and the fastest in the business. It can be installed at the rate of 1,000 square feet per day, per installer.

Following is a brief description of how FreeAxez builds a Gridd floor:

- First, a non-combustible foam Under Sheet is laid out so that the entire concrete slab is blanketed.This keeps the system quiet and stable.

- Next the steel base units, which already have 34 legs preinstalled on the underside, are quickly distributed along with Channel Plates and Corner Plates. This system is assembled simply and quickly,sort of like Legos. There are no posts, no glues, no screws, no fasteners and no tools needed. The floor is held together by gravity.

- The adjustable border components (referenced above) fill out the space with minimal. The ramp systems and electrical components are installed in a fraction of the time it takes with any other system.

Now let’s discuss two other Gridd products.

Gridd Power

The Gridd Power Raised Floor System is FreeAxez’s answer to a flexible power infrastructure to accommodate the aforementioned ever-changing demands of a corporate facility.

An electrical bus bar is defined as a conductor or group of conductors used for collecting electric power from incoming feeders, and distributing them to outgoing feeders. In other words, it is the junction in which all incoming and outgoing electrical current meets. Thus, the electrical bus bar collects electric power at one location.

In electrical power distribution, a bus bar is a metallic strip or bar that typically resides inside switchgear, panel board and busway enclosures for high-current power distribution.

Bus bars are popular because they distribute electricity with greater ease and flexibility than other more permanent forms of electrical power installation and distribution. Sometimes spelled busbar or buss bar, they are usually metallic strips made of copper, brass or aluminum that both ground and conduct electricity.

Bus bars are manufactured in a variety of coating materials which supply differing conductivity levels. They also come in a host of shapes and sizes, which also affect the ampacity of the product (Ampacity refers to the maximum amount of electrical current a conductor can carry before suffering critical levels of deterioration).

There are several other reasons why bus bars are popular.

The Benefits of a Bus Bar

As mentioned above, bus bars distribute electricity with ease and flexibility. Following is a list of the major benefits associated with the use of a bus bar system:

- Reduced Labor Costs: Bus bar installation is less expensive because it involves less construction labor and does not require the assistance of an expensive electrical specialist.

- Fast Installation: Bus bar systems can be installed very quickly. Projects are up and running faster—plus, with a bus bar system, power can be added, removed, or relocated easily with no downtime.

- Flexibility for the Future: Bus bars with plug-in units can be disconnected and reconfigured without the need to de-energize. No routine maintenance is required and expansion or remodeling is fast and less costly.

- Environmentally Friendly: Bus bars usually require fewer installation materials and plug-in outlets are reusable and re-locatable.

Reduced Cost of Ownership: Costs following installation are low. Bus bar systems reduce the need for construction and electrical work. Should a new power connection be needed, an additional plug-in unit can be placed at any point along the existing open-access slot.

More About Gridd Power

The Gridd Power Raised Floor System’s 50 Amp electrical bus track setup replaces obsolete power cabling with an integrated modular power structure that fits neatly under the floor using well-designed channels. Gridd Power makes it quick and easy to connect devices and appliances that need power to the Gridd system.

Gridd Power is at the cutting edge of power distribution technology. Its simplified, pre-configured part structure has the following components: feed module, track, interlink, power and data enclosure, general purpose floorbox, furniture interface and desk mount.

Here is a list of the features and benefits of a Gridd Power system:

- No need to use traditional field-wiring or hardwiring methods of installation.

- Components are pre-configured so installation or re-configuration along the track can be accomplished literally in seconds. Its 4-foot and 8-foot snap-together tracks will configure to any size power distribution system that meet the needs of almost any application.

- Uses 30% less copper than traditional wiring. Thus, this innovative bus bar technology is more efficient. Gridd Power also experiences less voltage drop, which reduces energy consumption.

- Gridd Power Whips (tap offs) deliver power to individual devices anywhere along the track, making installations, additions, moves, and changes easy to accomplish. No other system is more flexible.

- Gridd Power is SMART. Its monitoring system gives real time data on current loads.

- Gridd Power is powerful and delivers 50 Amp, 3-Phase, 208 Volt (V) and up to 15 kilowatts (kWh) of power in it’s easy-to-install track.

- Gridd Power is GREEN. It uses 30% less copper than traditional wiring methods and is completely reusable and movable.

Raised Access Floor Meets Augmented Reality

The last product to be discussed in this paper is Gridd Mobile.

Before Gridd Mobile, executing moves, adds and changes to wiring required an arsenal of tools to make even the most simple changes. Valuable time was spent pulling up carpet, opening ceilings, cutting into walls and even x-raying concrete.

Now, with Gridd Mobile, workers can see exact power, voice and data cabling right through the floor—right through the carpet, hard surface or steel flooring component—in an instant.

With the use of a smartphone or tablet , this revolutionary AR app provides:

- As-built drawings

- How-to videos

- Original site pictures

- Product information

Gridd Mobile plans range from Basic, which provides as-builts, project data, and technical resources to Platinum, which includes CAD design services and routine site visits to ensure the accuracy of the as-builts and attic stock. And our app is maintained with updates that improve the user’s experience.

This brings us to applications. Just what type of environments need a Gridd Raised Floor Cable Management System, Gridd Power, and Gridd Mobile?

The Application

FreeAxez’s cable management products can literally be used almost anywhere. Following is a list of some of the applications that can benefit from these products:

- Commercial Offices

- 911 Emergency, Surveillance and Control Room Operations

- Conference and Training Rooms, Computer Labs

- Universities, K-12 Schools, Classrooms, Libraries

- Courtrooms

- Museums and Displays or Exhibits

- Museums and Displays or Exhibits

- Casinos

- Hospital and Medical Facilities

- Banks

- Stock Markets

- TV/Radio/Recording Studios

- Retail

The FreeAxez Commitment

FreeAxez has an allegiance to innovation and creativity. We have positioned ourselves to respond to the rapid changes in our industry and are willing to take on the toughest problems—both now and in the future.

The world is changing: economic volatility is perhaps the foremost challenge on everyone’s mind; climate control is equally important; and new technologies constantly disrupt every industry in the world. The future is uncertain.

FreeAxez is committed to helping our clients take on the ever-changing challenges of our modern world.